DEVIL’S IN THE DETAILS: A SARTORIAL PROJECT

For those who know me, there are few things I can talk endlessly about: food, history, and tailoring. The knowledge of the latter subject stems from many many years of exposure. My father who wears suits everyday due to his profession would always talk to me about the importance of a suit.

Not only is a suit an article of style, it is for some their suit of armor, something they put to take on any obstacle at work and life. And for some, it is purely ceremonial, to be worn at funerals, weddings, and “formal” parties.

When I was young I recall, my father would take me with him to look at fabrics, and teach me about types of weaves, types of weights, and season variations of fabrics. After that we would beeline to his tailor to give him the fabric to start on his suit. I remember going back with him to the multiple fittings until seeing the amazing finished product, a suit made truly for him and him alone. Something about seeing something as simple and 2 dimensional as a piece a fabric, turn into a 3 dimensional garment.

Watching my father and his tailor go back and forth with hallmarks of fit, and playfully bicker with something as tedious as half a centimeter of sleeve length or sleeve pitch, both annoyed and astonished me.

Many years later, I have truly developed into the twin of my father, especially with the love of suits just like him. His love for quality, and handwork was something that I used to take for granted, but when a handmade sport coat off the rack on average costs 3,000 USD, and is for everyone but fits no one.

I had an epiphany; a suit or any garment made for you is a much better investment due to being made for you, and not having the uncharge of a designer label, or being pigeon held into “current” trends of the time.

With all the excessive time I have working from home, I decided to create a project: making a suit in this post-COVID world. Many people thought it was silly due to the majority of people having sweat pants and the t-shirt they slept in the night before as their new work uniform.

I want to create a suit that was classic, timeless, and first and foremost comfortable. I started by doing research, and I looked at a plethora of tailors in Mexico, Colombia, and Peru. The reason why I was looking at Latin America is not only due to the common fact that labor in other countries being less expensive, but is also due to the long history of clothing making, stemming from mainly Italian and Spanish tailoring styles that have been developed for decades. This coupled with a culture of having so much passion in their handwork, that speaks volumes.

I stumbled across one tailor located in Mexico City, who is an older man who has been tailoring for over 50 years.

I started by going to my primary alternations tailor. I had them measure me and take several pictures; front, sides and back. This is to show my morphology, and most skilled tailors can see if there are discrepancies in the measurements by pictures alone.

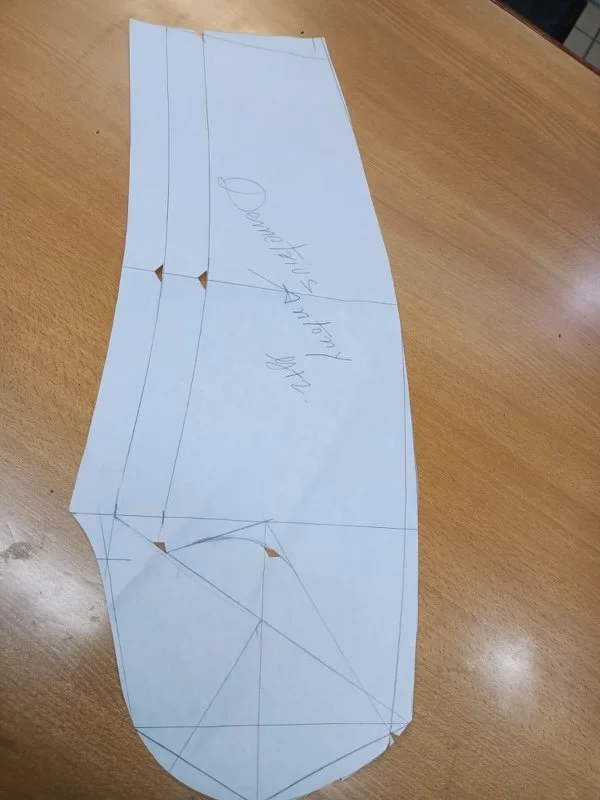

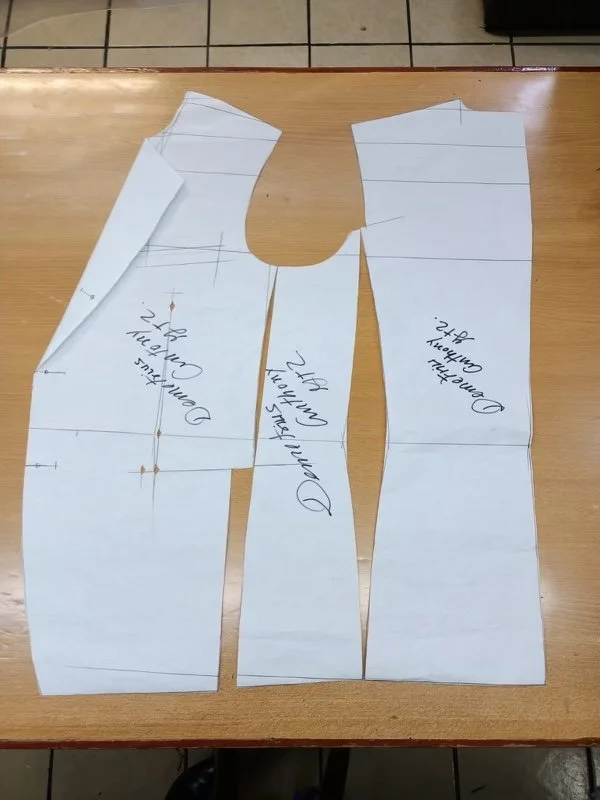

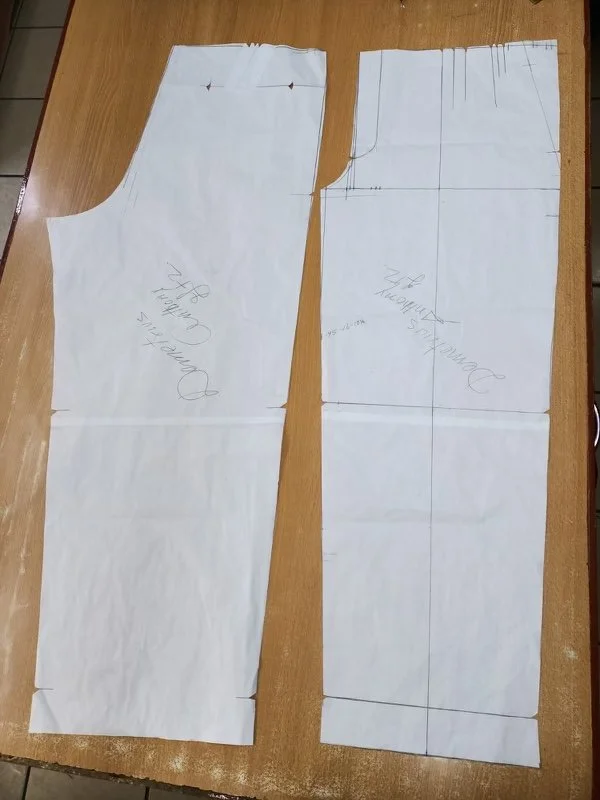

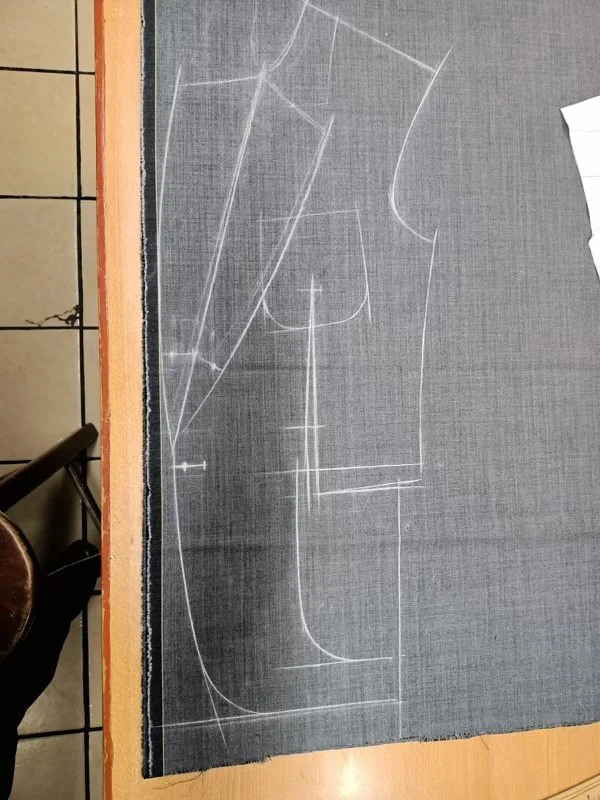

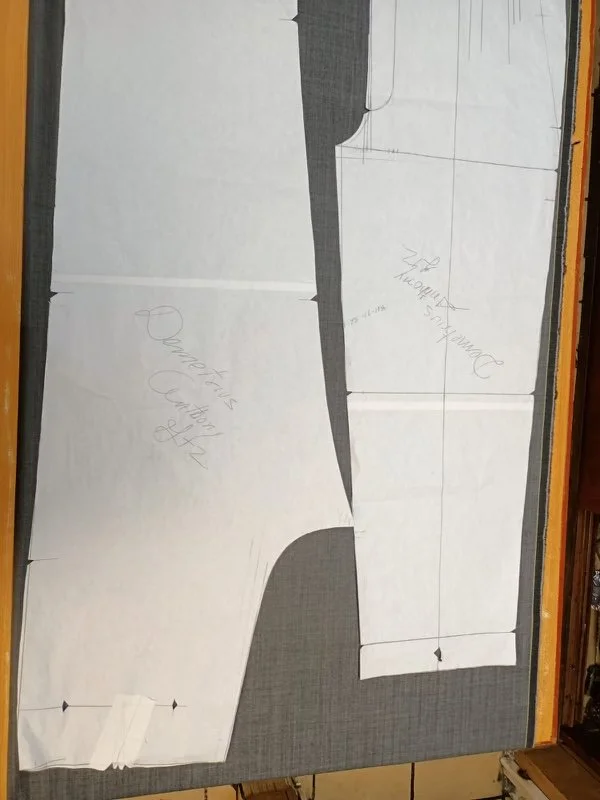

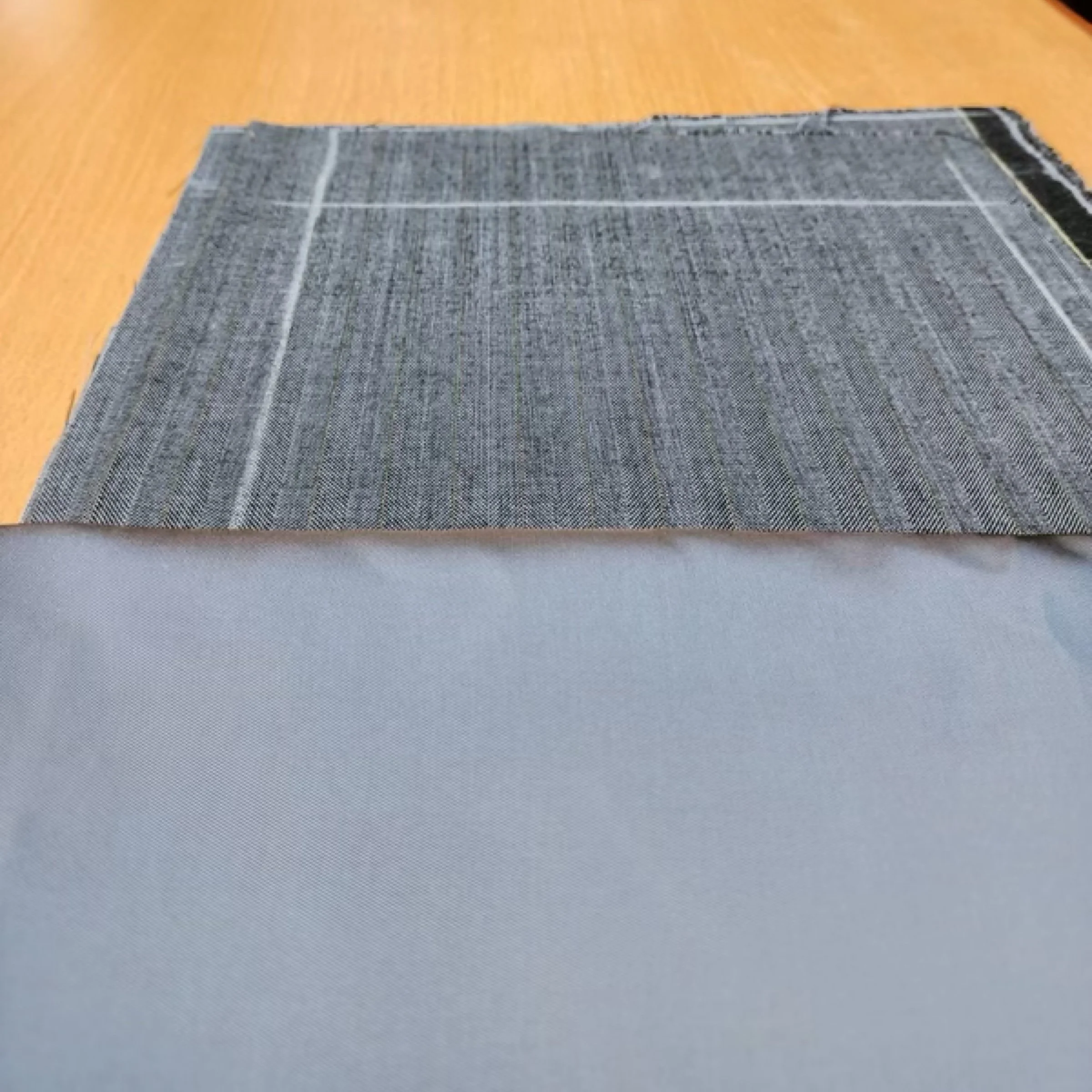

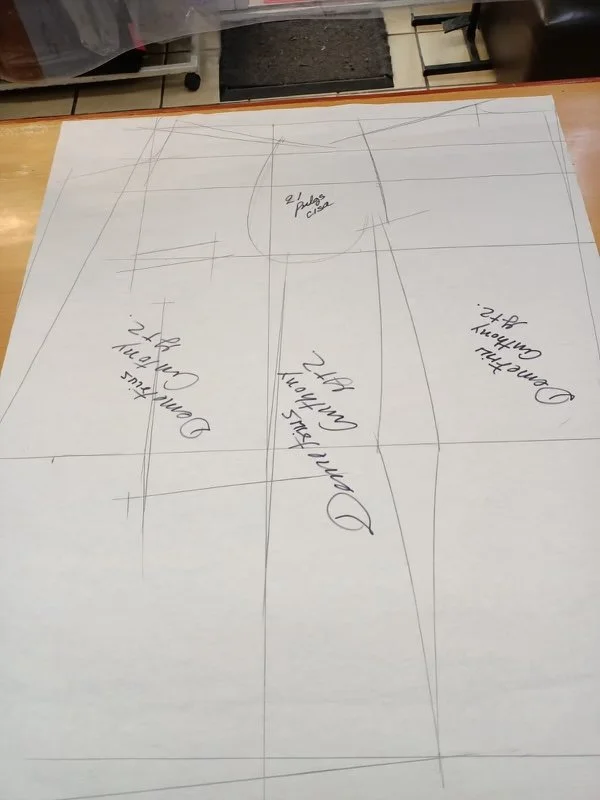

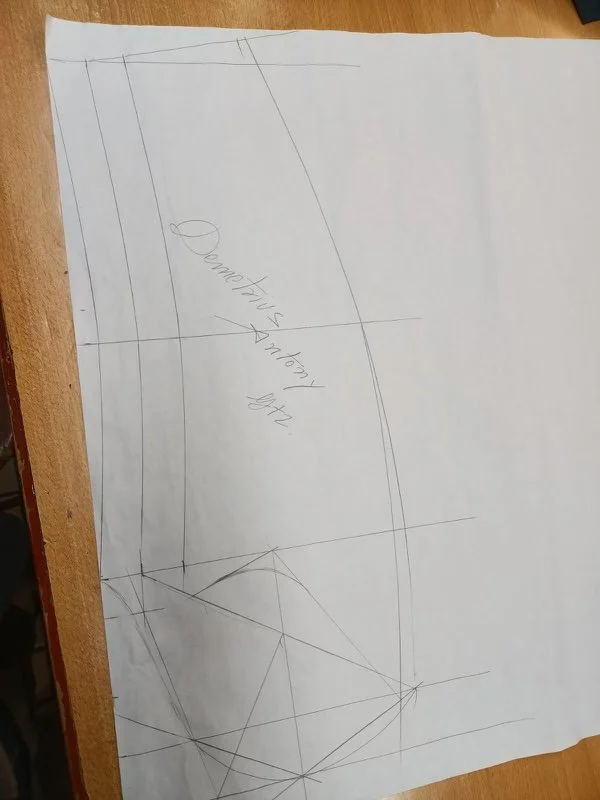

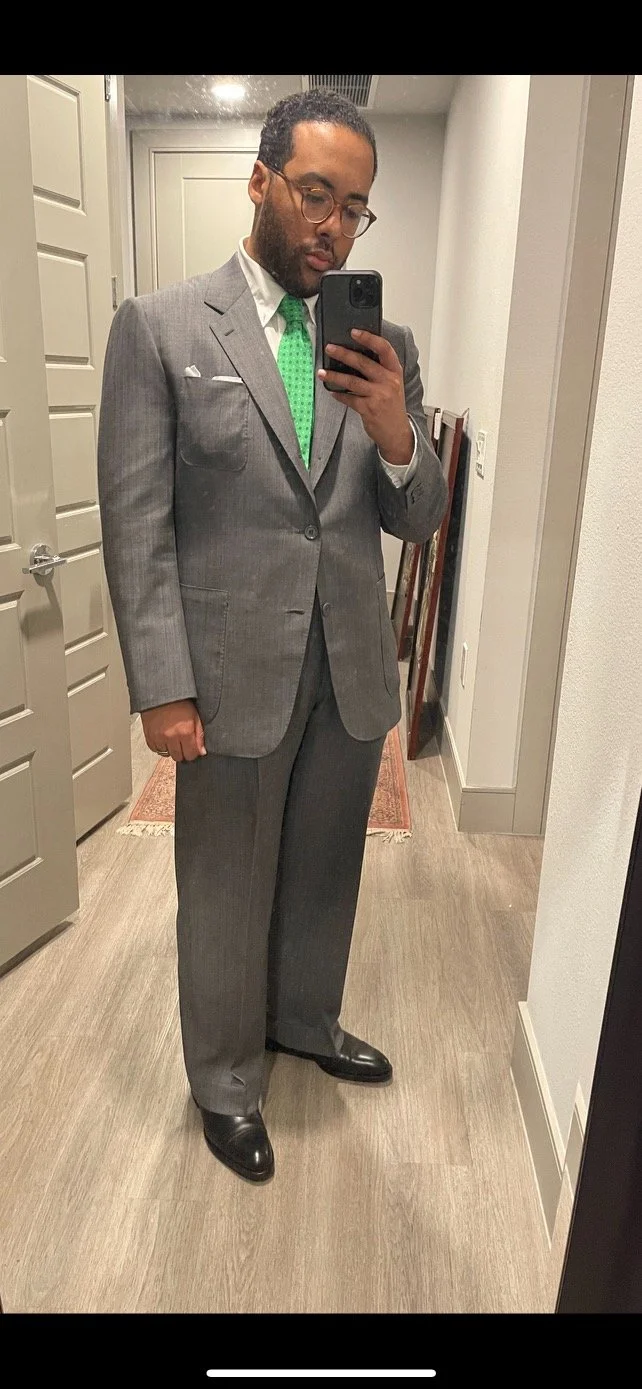

After giving the tailor the measurements, he showed me pictures of fabric, and I stumbled across a nice medium grey wool, with a prominent herringbone pattern. Something that is a slight departure from my usual shades of navy and blue. I asked the tailor to show me the process from A to Z, from drawing the pattern, striking it, sewing in the canvas, and finishing the buttonholes.

The entire process took a month. Once getting it, I was truly astonished by the details. It was truly a handmade garment, and everything from hand stitched canvas, to the sleeves put into the armhole by hand it was truly a work of art. My biggest needs for a suit are the armholes to be high, and for the rise of the trousers to be at, or slightly above the navel. The only qualms I have are the sleeves need to be wider, and more room and drape in the chest and back.

I really recommend others who are interested in suits, custom made to measure, and/or bespoke tailoring to do this project. Not only can you have a handmade suit for a fraction of the price, it is something that opens up new communication and relationships with tailors and people.